Brian A wrote:

Wow! Congrats!

I know right?

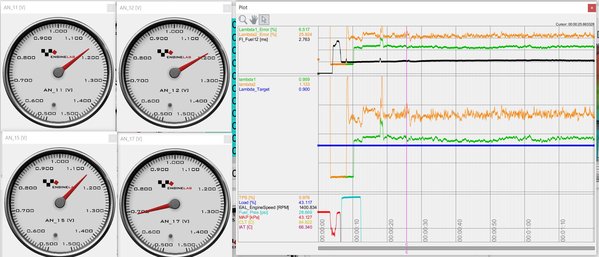

On the busy work list I've been thinking the NBO2 sensors were not working and I should make a change. Currently I have 18 O2 bungs. 12 in each cylinder, 4 in the 1st collectors, 2 in the 2nd (bank) collectors. Sensors wise I have 4 NB O2 in the 1st collectors and 2 WO2 in the banks. I was thinking the ECU was just not reading the NB sensors correctly...all the analog inputs have a 5V pullup which can be very helpful but isn't current for a NBO2 sensor so when I got what looked like gibberish result I wasn't surprised. That got me to thinking a better setup would be 4 WB sensors and I've been pondering how to explain that to Lana as it will cost money.

This evening I spent some time digging through log data...the NB sensor are working just not the way I expected. I was displaying a lambda based on a simple lookup table created from the bosch data sheet...but it looks like the pullup is buggering it so the table was all wrong. its supposed to be 1.0 lambda at about 0.5V, rich above, lean below with a big dead zone from like 0.3-0.7. that's what I planned for but not what I have....it looks like I'm reading 0.5-1.5V with 1.0 lambda at about 1.0V, lean below, rich above so backwards and offset 0.5V

This shows i had a problem in the 10-12 group with 1 dropping out intermittently

11=1-3

12=4-6

15=7-9

17=10-12

Attachment:

log review.JPG [ 228.5 KiB | Viewed 3917 times ]

log review.JPG [ 228.5 KiB | Viewed 3917 times ]

here is where its clear something has gone wrong in the 7-9 group with that NB not in anyway matching the others...which I now Know was a dead #8